Are you struggling to understand how an epicyclic gear train works? You’re not alone.

Many find the concept confusing, especially when terms like simple planetary gear train and sun gear meshes are thrown around.

But don’t worry. This guide will break down these essentials, making it simple and clear.

Let’s dive into the fascinating world of gears and gear trains and see how these components work together seamlessly.

What is an Epicyclic Gear Train?

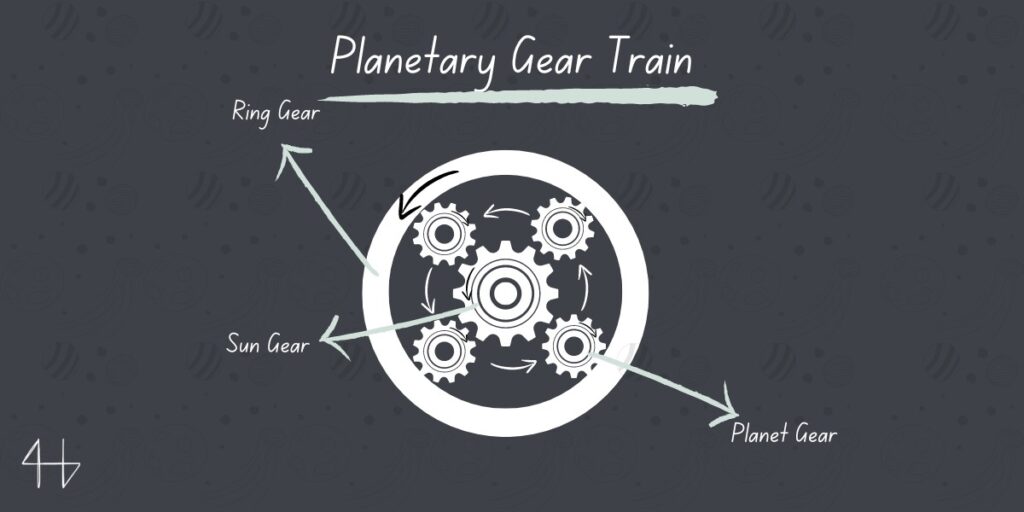

An epicyclic gear train, also known as a planetary gear train, looks like planets orbiting the sun – really cool design.

In this system, a central sun gear is orbited by multiple planet gears, which are held in place by an outer ring gear.

Working principle of an Epicyclic Gear Train

The working principle of a planetary gear train involves the interaction of three main components: the sun gear, the planet gears, and the ring gear. Here’s how it works:

Sun Gear: The central gear, called the sun gear, transmits torque to the planet’s gears.

Planet Gears: These gears orbit around the sun gear and mesh with both the sun gear and the ring gear. The planet gears are mounted on a movable carrier that can rotate. (The carrier is not shown in the image above.)

Ring Gear: The outer ring gear has internal teeth that mesh with the planet’s gears.

The sun and ring gear rotate in the same direction.

The arrangement of these gears can produce different output speeds and torques depending on which component is held stationary and which component is used as the input or output. There are three basic configurations:

Planet Carrier as Output: When the sun gear is the input and the ring gear is held stationary, the planet carrier becomes the output, resulting in increased torque and reduced speed. Additionally, when the number of planet gears in the system is increased, the power transmission is also increased.

Sun Gear as Output: When the planet carrier is the input and the ring gear is held stationary, the sun gear becomes the output, providing a different speed and torque ratio.

Ring Gear as Output: When the sun gear is the input and the planet carrier is held stationary, the ring gear becomes the output, often resulting in increased speed and reduced torque.

By manipulating which component is the input, output, or stationary, a planetary gear train can achieve various speed and torque conversions, making it highly versatile for applications such as automatic transmissions in vehicles.

Understanding the working principle of an epicyclic gear train is crucial. The key takeaway is: that when the ring gear rotates, the planet gear revolves around the sun gear, creating different speeds and directions.

This interaction determines the overall gear ratio, making the system efficient and versatile for various applications.

Advantages vs Disadvantages of an Epicyclic gear train

Planetary gear trains offer high gear ratios in compact spaces, making them efficient and versatile.

However, their complexity can lead to maintenance challenges. The precise number of teeth in each gear affects performance and efficiency. Balancing these factors is key to leveraging the benefits of planetary gear trains.

Advantages

Disadvantages

Where to find Epicyclic Gear Train?

Epicyclic Gear Trains are found in various applications due to their efficiency and compact design.

These systems, featuring ring gears and multiple gear teeth engagements, are used in several key areas. Here’s a look at where you might encounter them:

3d printer filament extruder

The planetary gear train plays a crucial role in enhancing the performance of a 3D printer filament extruder.

This system often uses a compound epicyclic gear train, which includes multiple stages of spur gears to achieve the desired speed ratio.

This setup ensures precise control over filament extrusion, leading to higher print quality and consistency.

Robotics

In robotics, the planetary gear train plays a crucial role in enhancing performance. The unique configuration of epicyclic gears, including planet and sun gears, allows for a high torque ratio within a compact space.

This efficiency is vital for robotic arms and mobile robots, enabling precise movements and powerful actions without sacrificing space or weight.

Automotive transmissions

In automotive transmissions, especially in hybrid vehicle power transmissions, the planetary gear train plays a crucial role.

This system uses simple planetary gears to efficiently manage power distribution. Integrating sun and ring gears, enables smooth transitions between different power modes, enhancing both performance and fuel efficiency.

The compact design of these gear trains makes them ideal for complex transmission systems found in modern vehicles.

Key Considerations For Successfully Designing an Epicyclic Gear Train

Designing a successful epicyclic gear train involves several crucial considerations. First, you need to understand how the planetary gear system operates.

The planetary gears mesh with the sun gear and the ring gear, which requires precise alignment and sizing to ensure smooth operation. Each planet gear rotates around the sun gear while also rotating on its axis, creating complex motion that must be carefully managed.

Pay close attention to gear ratios, material selection, and load distribution to achieve optimal performance and durability. By addressing these factors, you can create an efficient and reliable gear train system.

Wrapping up

In summary, epicyclic gear trains offer remarkable efficiency and versatility in mechanical systems. By understanding how planet gears rotate around a central sun gear, and how they interact with a fixed ring gear, you can appreciate their complex functionality.

Whether dealing with compound planetary gears or simpler designs, recognizing the role each component plays is crucial. This knowledge not only clarifies how these systems operate but also highlights their advantages in various engineering applications.

FAQs about Epicyclic Gear Trains:

How does an epicyclic gear train differ from a traditional gear train?

An epicyclic gear train, also known as a planetary gear train, consists of a central sun gear, planet gears that orbit around the sun gear, and an outer ring gear with internal teeth.

Traditional gear trains typically involve a series of gears in a fixed position with one gear meshing directly with another.

The unique arrangement of an epicyclic gear train allows for higher power density, multiple speed ratios, and more compact designs compared to traditional gear trains.

What applications commonly use epicyclic gear trains?

Epicyclic gear trains are widely used in applications where compact size and high torque are important.

Common uses include automatic transmissions in vehicles, industrial machinery, aerospace mechanisms, robotics, and even wind turbines.

Their versatility and efficiency make them suitable for a broad range of mechanical systems.

What are the maintenance considerations for epicyclic gear trains?

Maintaining an epicyclic gear train requires careful attention to lubrication, alignment, and wear of the gears.

Proper lubrication is crucial to prevent excessive wear and overheating. Regular inspections are needed to check for misalignment and wear on the gears and bearings.

Due to their complex design, maintenance can be more challenging and time-consuming compared to simpler gear systems, but regular maintenance is essential to ensure the longevity and efficient operation of the gear train.