Struggling with complex machinery? Understanding compound gear trains can seem daunting, especially for beginners.

When dealing with intricate systems, I like to focus on the basics. When working with gear trains, especially compound gear trains, a basic understanding of mechanical power transmission goes a long way.

This post will break down the essentials of compound gear trains and explain how gear ratios work within them.

Let’s get started.

What is a compound gear train?

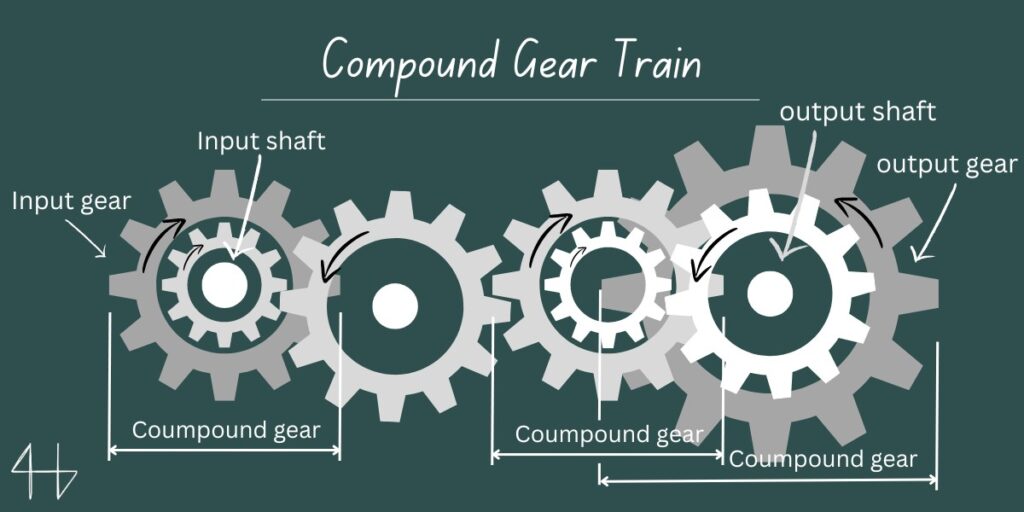

A compound gear train, basically put, is a gear train that makes use of compound gears. This involves multiple gears working together on the same axis.

This setup allows for different gear ratios, enabling precise control over speed and torque.

Unlike simple gear trains, compound gear trains can achieve the same speed for multiple outputs, making them essential in complex machinery.

The working principle of a compound gear train

A compound gear train uses multiple gear wheels, where at least one shaft holds two gears of different sizes.

This setup allows for more control over the overall gear ratio. The overall gear ratio can be calculated by multiplying individual gear ratios, affecting the speed and torque of the output gear.

Advantages vs Disadvantages of a Compound gear train

A compound gear train offers several advantages, such as higher torque and compact design.

By using intermediate gears and idler gears, you can achieve desired gear ratios while maintaining the same direction of rotation.

However, they can be complex to design and may introduce more friction.

Advantages

Disadvantages

Compound gear train application

Compound gear trains are widely used in various applications due to their efficiency and versatility.

They allow for significant changes in speed and torque between the input and output shafts. By using multiple gears and an intermediate gear, these systems can achieve precise control over mechanical movements.

Here are some common applications of compound gear trains:

1. Automotive Transmissions Systems: Achieve different speeds and torque.

2. Clocks and Watches: Maintain accurate timekeeping.

3. Industrial Machinery: Provide necessary force and speed.

4. Robotics: Enable precise movement and control.

5. Conveyor Systems: Ensure smooth and efficient material handling.

Automobile transmission systems

Automobile transmission systems rely heavily on different gear ratios to function effectively.

Inside a transmission, the input gear connects to the engine and transfers power to the gearbox. The gearbox then adjusts this power through various gear ratios to provide the necessary torque and speed.

This adjustment is essential for optimizing the vehicle’s performance under different driving conditions.

Clocks and Watches

In clocks and watches, precision is everything.

These devices often use a series of gear wheels to achieve accurate timekeeping. When you have two gears working together, the gear ratio between them determines how they interact.

The final gear ratio in such a setup ensures that the hands of the clock move at the correct speed, translating the gear movement into precise time intervals.

By understanding how these gear wheels and their ratios work, we can appreciate the intricate engineering behind our timepieces.

Industrial Machinery

In industrial machinery, meshing gears are fundamental for transferring motion and torque efficiently.

When multiple gears are involved, it’s essential to maintain the same gear ratio to ensure smooth operation. Often, these systems incorporate more than one gear to distribute the load and enhance performance.

This arrangement not only optimizes efficiency but also extends the machinery’s lifespan by reducing wear on individual gears.

Understanding how these components work together is crucial for anyone working with complex mechanical systems.

Robotics

In robotics, the precision of gear trains is crucial for accurate motion control.

The input and output shaft system transfers rotational movement through various gears, impacting the robot’s functionality. By adjusting the input shaft speed, engineers can fine-tune the robot’s performance.

An idler gear can be used to change the direction of rotation or adjust the gear ratio without altering the speed of the input shaft.

Understanding these components helps in designing more efficient and responsive robotic systems.

Conveyor Systems

Conveyor systems are integral to many industries, handling materials efficiently through automated processes.

At the heart of these systems are gear trains, where gear teeth play a crucial role in controlling movement. For precise control, understanding the first gear ratio is essential.

This ratio dictates how speed and torque are transferred through the system.

When reversing the direction, a reverse gear is used to ensure smooth operation. Properly managing these components ensures reliable and efficient conveyor performance.

Key considerations for designing a compound gear train

Designing a compound gear train involves several crucial considerations to ensure optimal performance.

Gear ratio is fundamental; it dictates the desired gear ratios needed to achieve specific speed and torque.

Choose gear materials carefully for their strength, durability, and ability to handle wear and lubrication effectively. Note that when meshing gears are made of the same materials, they tend to wear out faster than if they were made of different materials.

The type of gear—whether spur, helical, bevel, or worm—affects load distribution and operational efficiency.

Precision in alignment and tolerances is vital for smooth operation, impacting manufacturing processes and the overall lifespan of the gear train.

Proper shaft design and bearing selection are essential for stability and reduced friction.

Additionally, we need to consider potential noise and vibrations, which can influence the system’s performance and user comfort.

Balancing these factors ensures your compound gear train operates reliably and efficiently.

Compound vs simple gear trains

When comparing compound and simple gear trains, the main difference lies in their construction and functionality.

A simple gear train consists of a series of gears connected in sequence, with each gear pair rotating on the same shaft. This setup is straightforward and efficient for basic applications.

On the other hand, a compound gear train incorporates multiple gear pairs that are mounted on different shafts.

This arrangement allows for more complex gear ratios and greater mechanical advantage. By using different shafts, compound gear trains can achieve higher gear ratios and more precise control, making them ideal for intricate machinery.

Wrapping up and My Experience with Compound gear trains

Wrapping up, and mastering compound gear trains can transform your understanding of gear system efficiency.

I once faced a challenging project where optimizing the gear train arrangement was crucial. Adjusting the gears improved the output speed dramatically, saving time and costs.

By analyzing each gear ratio and its impact on the overall system, I learned how small adjustments can lead to significant improvements.

Whether you’re a hobbyist or a professional, grasping these concepts enhances your ability to design effective gear systems. Implementing compound gear trains wisely can make a notable difference in your mechanical projects.