What is a Gear Train? Understanding gear trains is crucial for anyone diving into engineering. Imagine a car that struggles to climb hills or an electric drill that can’t handle tough materials. Frustrating, right?

That’s where gear trains come in, ensuring smooth and efficient power transmission.

Let’s explore why gear trains and gear ratios are essential in engineering.

What is a gear train?

A gear train consists of two or more gears working together to transmit motion and force. The primary purpose is to change the speed ratio between the input and output gears. This adjustment allows machines to operate efficiently at various speeds and torque levels.

Reasons why you should know about gear trains

Understanding gear trains is vital because they directly impact the efficiency and functionality of machines. Knowing about the overall gear ratio and different gear ratios helps optimize performance.

Gear trains play a crucial role in various applications, from vehicles to industrial machinery, ensuring smooth and effective operation.

Types of gear trains

Gear trains come in various types, each suited for specific applications and performance needs.

From planetary gear trains known for their high torque capacity to compound gear trains that combine multiple gears for increased efficiency, and double reduction gears for significant speed reduction, understanding these types is essential.

Simple gear train

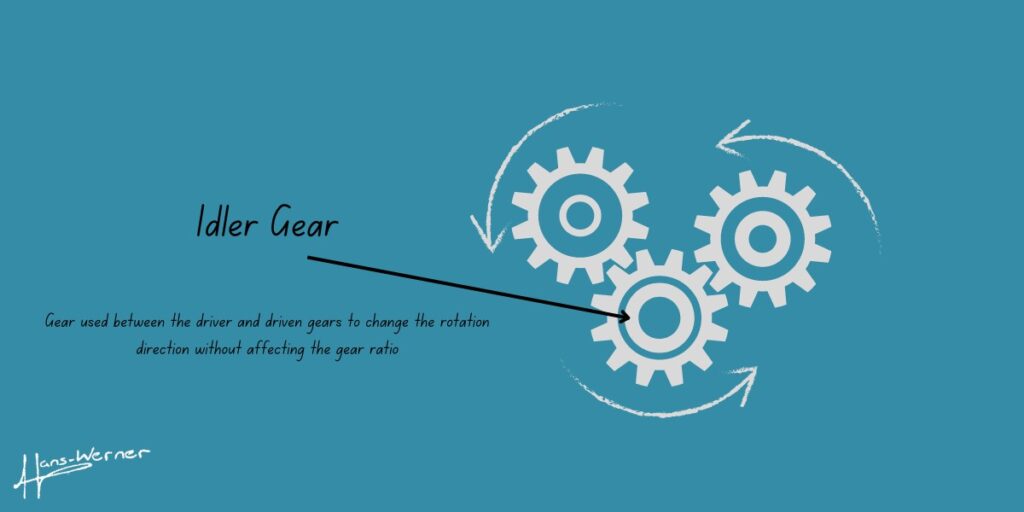

A simple gear train consists of two or more gears meshed together, often using spur gears and bevel gears.

An idler gear can be added between the driver and driven gears to change the rotation direction without affecting the gear ratio. Helical gears can also be used for smoother and quieter operation.

Compound gear train

A compound gear train utilizes intermediate gears to achieve complex speed ratios between the driving gear and the driven gear.

This setup allows for fine-tuning speed and torque transmission, making it ideal for applications requiring precise control over mechanical output.

Understanding how intermediate gears affect the overall speed ratio is key to optimizing performance in such gear systems.

Epicyclic gear train

Epicyclic gear train, also known as planetary gear train, consist of planet gears revolving around a central sun gear.

These gears are housed within a ring gear, allowing for compact and efficient power transmission.

Epicyclic gear trains are favored for their high torque and load distribution capabilities, making them ideal for applications in automotive and industrial machinery.

Reverted gear train

A reverted gear train uses multiple gears in a specific layout where the input and output shafts are collinear.

This setup is efficient for achieving a high gear reduction ratio. The meshing gears in this arrangement help in compact design while maintaining the necessary torque and speed adjustments.

Rack and Pinion gear train

The rack and pinion gear train converts rotational motion from the input gear into linear motion.

Unlike gear wheels that rotate at the same speed, this system uses a gear to move a straight rack, making it ideal for steering mechanisms and precise movements in machinery.

Key Considerations For Successfully using a gear train

When utilizing a gear train, understanding speed ratios and how to calculate gear ratios are paramount.

The choice of the first gear significantly affects overall performance, influencing both speed and torque.

Properly calculated gear ratios ensure optimal efficiency and smooth operation across various applications.

Calculating the gear ratio

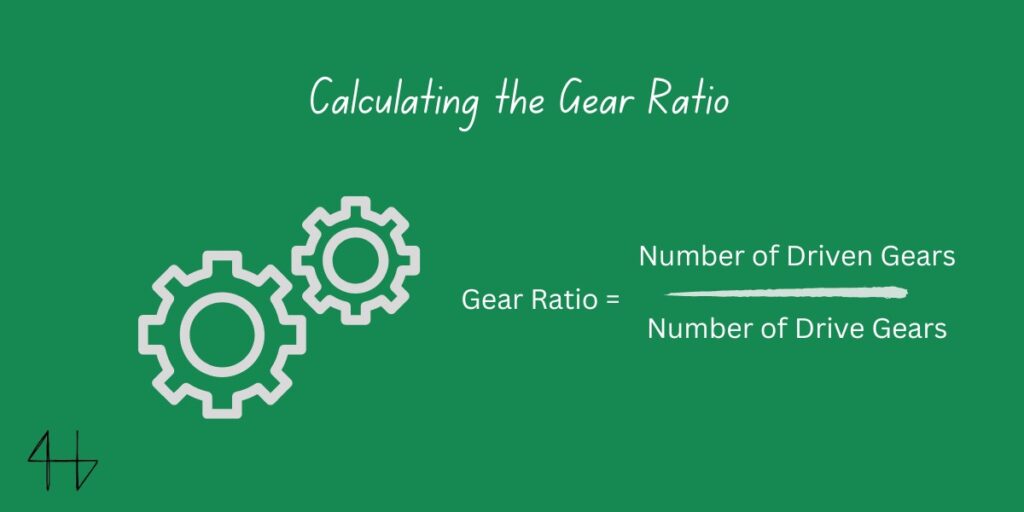

To determine the gear ratio of a gear train, you need to consider the number of teeth on the input and output gears.

The gear ratio is calculated by dividing the number of teeth on the output gear by the number on the input gear.

This ratio determines how much the input speed and torque are modified by the gear train configuration. Understanding this calculation is fundamental for designing efficient mechanical systems.

Next Level: Gear train project ideas

For those ready to delve deeper into gear systems, exploring reverted gear trains can offer exciting project opportunities.

Experiment with different rotational speeds and gear configurations to understand how these systems impact efficiency and performance in various applications.

Get hands-on to uncover the intricacies of gear dynamics firsthand.

I recommend 3D printing some of these gear trains if you can.

Wrapping Up and My Experience With Gear Trains

In conclusion, gear trains are the backbone of mechanical systems, influencing everything from speed to torque.

One intriguing example is the French parallel window gear system, which utilizes two gears and an intermediate gear to transmit motion between two parallel shafts efficiently.

Understanding these concepts empowers engineers to create innovative and effective designs for various applications.

FAQs

Where are gear trains used?

Gear trains find applications in diverse industries and devices worldwide.

They are essential components in wind turbines, ensuring optimal energy conversion from wind to electricity. In everyday items like electric toothbrushes, gear trains drive the brush head smoothly.

They are also crucial in automotive transmissions, industrial machinery, and any system needing to transmit power efficiently and reliably.

How do gear trains work?

Gear trains operate by transmitting power from one gear to another, often involving more than one gear to achieve the desired speed and torque outputs.

The input gear drives the system, rotating a connected driven gear, which in turn rotates the output shaft. This mechanical arrangement allows for precise control and adaptation of rotational motion in various mechanical devices.

What do gear trains do?

Gear trains are essential for adjusting the rotational motion between input and output components to achieve the desired output speed.

By connecting gears that rotate at different speeds, gear trains transmit power effectively while altering torque levels as needed. This ability makes them indispensable in numerous mechanical applications.