When I first started designing gear trains for my projects, I had no idea where to start. My research didn’t help much either because I didn’t understand the gear terminology.

So here I will give you the help that I needed when I first started – a list of the most important terminology you’ll come across when designing gears AND pictures to help you out.

If something is still unclear, please contact me and I will help you out.

Gear Terminology

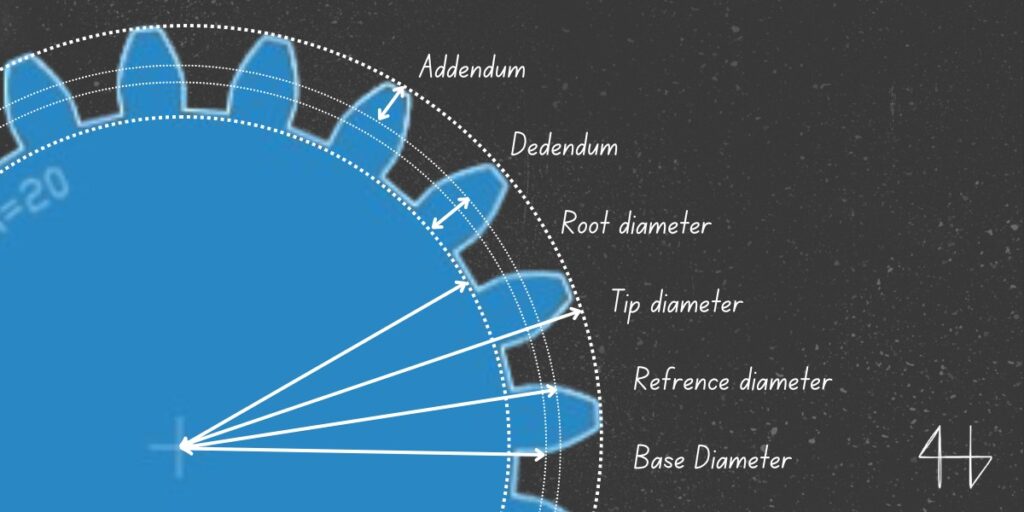

Addendum: The height of a gear tooth above the pitch circle.

Dedendum: The depth of a gear tooth below the pitch circle.

Root Diameter: The diameter of the circle at the base of the gear teeth

Tip / Outside Diameter: The diameter of the circle that touches the outermost points of the gear teeth.

Base diameter: An imaginary circle used as a reference to design the curved shape of the gear teeth.

Reference / Pitch Diameter: The diameter of the pitch circle.

Reference / Pitch Circle: The circle that represents the effective contact diameter of a gear, where the speed is measured.

Circular Pitch: The distance between the same point on two consecutive teeth along the pitch circle.

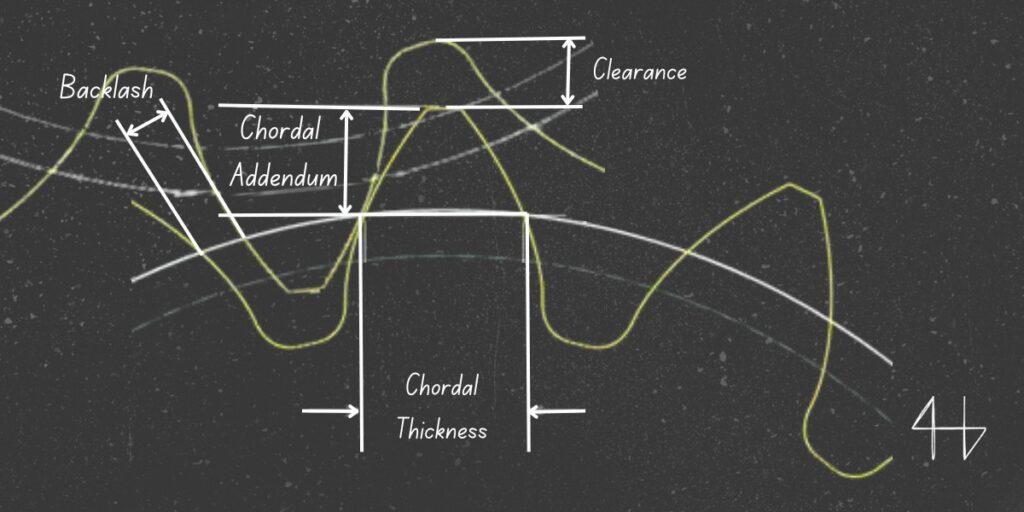

Backlash: The small gap or clearance between the teeth of two meshing gears.

Chordal Thickness: The thickness of a gear tooth measured along a straight line (chord) that crosses the pitch circle.

Chordal Addendum: The distance from the top of a tooth to the point where the pitch circle crosses the tooth profile.

Clearance: The space between the bottom of one gear’s tooth and the top of the mating gear’s tooth.

Center Distance: The distance between the centers of two gears that are working together.

Diametral Pitch: The number of teeth per unit of pitch diameter.

Gear Axis: The central line around which a gear rotates.

Module: The metric equivalent of diametral pitch, representing teeth per millimeter of pitch diameter.

Pinion: The smaller gear in a pair of meshing gears.

Pitch Point: The point where the pitch circles of two mating gears touch.

Pressure Angle: The angle between the gear tooth face and the tangent to the gear wheel at the pitch point.

Tooth Profile: The shape of the gear tooth surface.

Tooth Surface: The smooth outer part of a gear tooth that makes contact with other gears. This surface is carefully shapedand polished to reduce friction and wear during operation.

Velocity Ratio: The ratio of the speed of the input gear to the speed of the output gear.

Working Depth: The total depth of gear tooth engagement, from the top of one tooth to the bottom of the mating tooth.

Gear Formulas

| Term | Formula |

|---|---|

| Addendum | 1.0 ÷ diametral pitch |

| Clearance | 0.157 ÷ diametral pitch |

| Diametral Pitch | Number of teeth ÷ pitch diameter |

| Number of Teeth | Pitch diameter * diametral pitch |

| Outside Diameter | (Number of teeth + 2) ÷ diametral pitch |

| Pitch Diameter | Number of teeth ÷ diametral pitch |

| Tooth Thickness | 1.5708 ÷ diametral pitch |

| Whole Depth | 2.157 ÷ diametral pitch |

| Working Depth | 2 ÷ diametral pitch |

Final words

If you need a more in-depth understanding of gear terminology, there are sites out there that are somewhat confusing, but I hope that my straight forward approach has helped you out.

Once again, message me if you have any questions or if anything is unclear.