Gears are all around us, powering the machines and devices we use every day. But still, understanding the different types of gear trains is often overlooked even by experienced engineers.

This oversight can lead to suboptimal designs, where efficiency, precision, or even the lifespan of a machine might be compromised.

Here I will cover the 4 types of gear trains you should know about.

What is a gear train?

First things first… what is a gear train?

A gear train is a mechanism composed of two or more gears working together to transmit motion and torque.

The main function of a gear train is to change the gear ratio between the input and output gears which directly affects the speed ratio and torque. By meshing different size of gears you can either increase or decrease the rotational speed and force of the output compared to the input.

Knowing how these gears work helps in designing systems that perform as expected.

The Importance of Gear Ratios

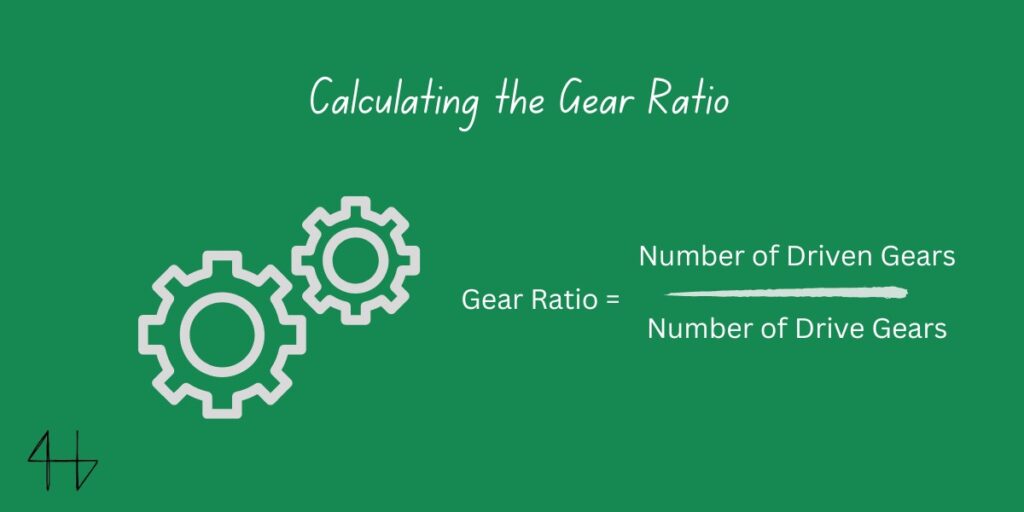

The gear ratio determines the relationship between the speed and torque of the input and output shafts.

For instance, if you need to reduce speed but increase torque — like in heavy machinery (cranes, tractors, and hydrolic presses) — a high gear ratio with a larger driven gear is essential.

Conversely, for applications where speed is more important than torque, such as in small electric motors, a lower gear ratio is preferable.

Why You Can’t Overlook Gear Trains in Your Designs

Without it, you might struggle to achieve the desired performance in terms of speed, torque, or even durability. And when you use the wrong type of gear train, you are likely end up with a much larger product than fits in your scope.

By knowing which gear train to use where, you’ll make smarter design choices that lead to more reliable and efficient machines.

Why you should know the 4 types of gear trains

Each type of gear train affects how gears rotate and the relationship between input and output gears. Knowing these will allow you to choose the right configuration for your needs, whether you want to maximize efficiency, control speed or adjust torque.

By knowing how different gear trains affect the meshing of gears you can design more robust, efficient and compact systems that meet specific performance requirements.

Here are the 4 types of gear trains:

- Simple gear train

- Compound gear train

- Epicyclic (planetary) gear train

- Reverted gear train

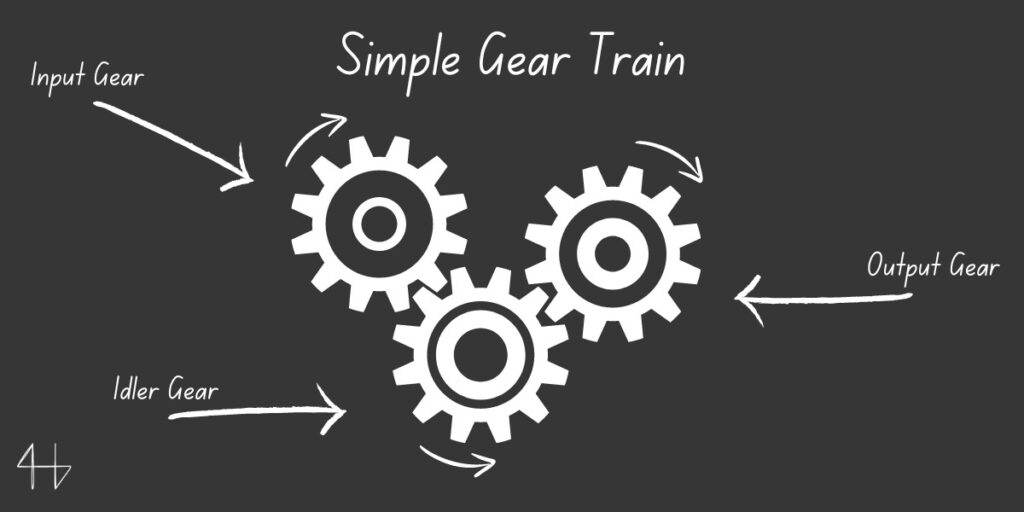

Simple gear train

A simple gear train has only a few components, usually spur gears and an idler gear.

In this setup the motion is transferred directly from one gear to another with minimal complexity. As the input gear rotates, the meshed teeth push on eachother reating rotation and a transfer of torque between the input gear and the gear next in line. In the above example, the idler gear rotates.

The primary function of an idler gear in this configuration is to space and smooth the engagement of the input and output (driving and driven) gears.

Finally, the output gear rotates at the required speed and torque.

This is a super simple example that’ll probably never come up in real life.

This type of gear train is simple and cheap so is good for applications where direct gear to gear transmission is enough.

It’s good for situations where simplicity and reliability is key.

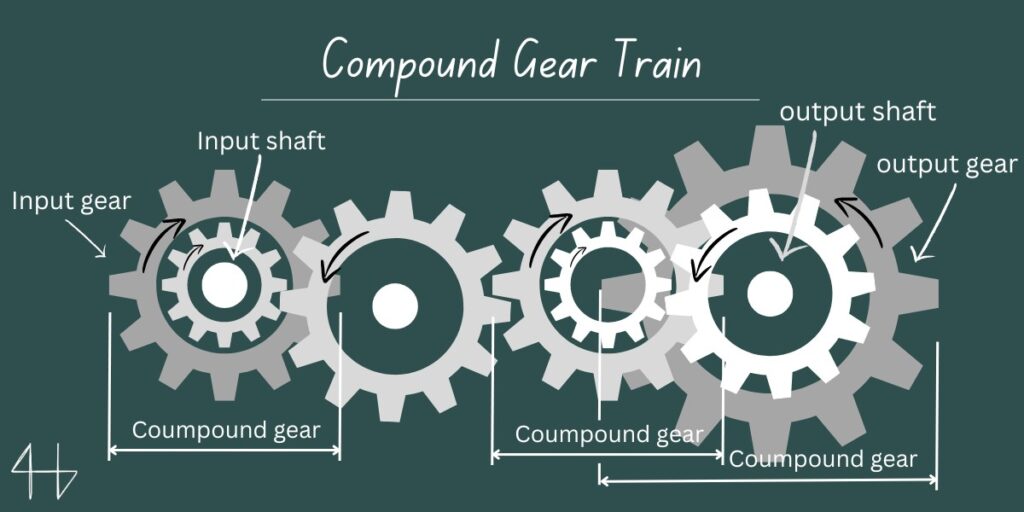

Compound gear train

A compound gear train has multiple pairs of gears on one shaft, allows for more flexibility in achieving a specific gear ratio.

In this setup intermediate gears are used to connect the driving gear to the driven gear, allowing the system to transmit torque across multiple stages. This is good when a big change in speed or torque is required in a small space.

By stacking gears on shared shafts, compound gear trains can achieve higher or lower gear ratios than simple gear trains. So compound gear trains are good for more complex and demanding applications.

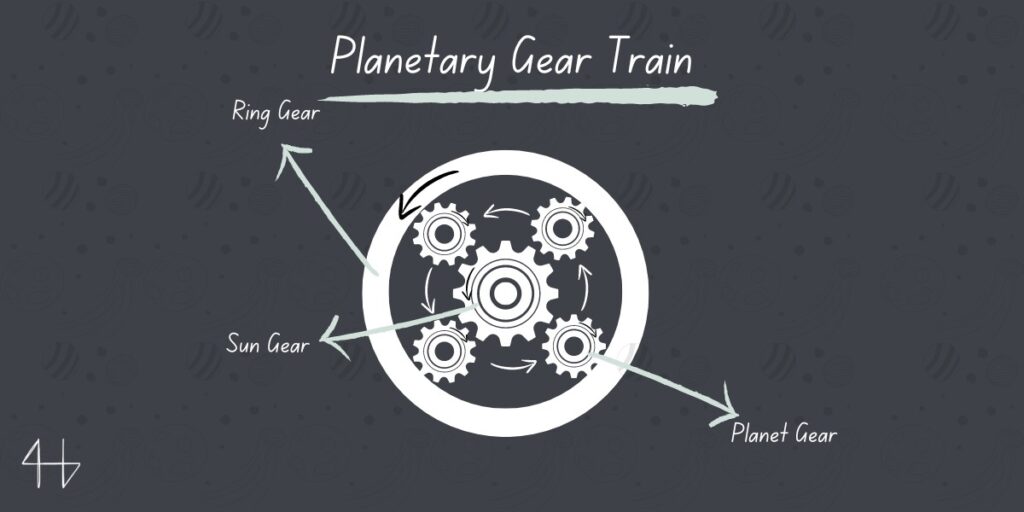

Epicyclic gear train (planetary gear train)

An epicyclic gear train, also known as a planetary gear train, is a more complex system that offers versatility and high torque in a small package.

This gear train has three main components: the central sun gear, planet gears and an outer ring gear. The planet gears orbit around the central sun gear while meshing with the outer ring gear.

The fun part of a planetary gear train is that the uses drastically change depending on which part of the gear train is held stationary.

- Sun gear stationary

- Planetary carrier becomes the output

- Ring gear serves as the input

- The gear ratio will be determined by the number of teeth on the ring gear and the planet gears.

- Output speed is reduced,

- Torque is increased significantly

- Ring gear stationary:

- The planets orbit around the sun gear

- Sun gear is the input,

- Planetary carrier is the output.

- Gear ratio can be calculated based on the number of teeth on the sun gear and the planet gears

- Different torque and speed output compared to when the sun gear is stationary

- This setup is often used for applications requiring high torque and lower speeds.

- Planetary carrier stationary:

- The sun and ring gears can rotate relative to each other

- The system to function as a differential, where both the sun gear and ring gear can provide input and output.

- The gear ratio is determined by the number of teeth on the sun gear and the ring gear

- This setup can enable complex motion and torque distributions, making it suitable for applications like automotive differentials

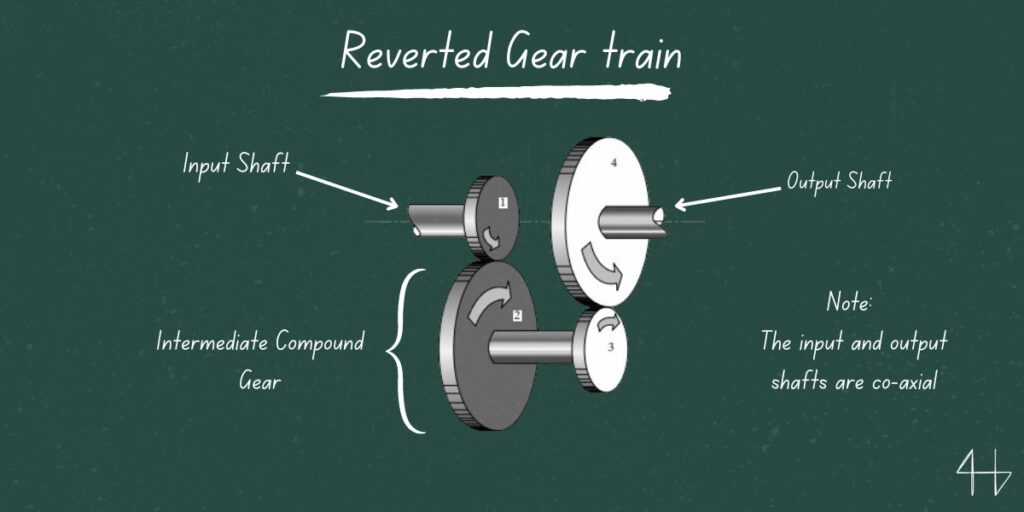

Reverted gear train

A reverted gear train is a special configuration where the input and output gear are on the same axis.

This is achieved by choosing the gear reduction ratio so that the distance between the centres of the first gear and the intermediate gears is the same as the distance between the centres of the intermediate gears and the output gear.

The main advantage of this is that it allows for big speed reduction or torque increase in a small space.

This makes reverted gear trains good for applications that require precise alignment and high torque in a small area.

Conclusion and My Experience with Gear Trains

Gear trains are used in many engineering applications, from simple machines to complex systems.

Knowing the different types of gear trains and when to use them is key to optimising performance whether you’re working with simple mechanisms or complex designs. From simple to more complex setups like reverted gear trains each has its own benefits depending on your requirements.

In my experience having a good understanding of these systems has been very useful in designing efficient machines.

Mastering gear trains not only improves your engineering skills but also opens up more innovative and effective solutions.

FAQs

How many types of gear trains are there?

There are four types of gear trains: simple gear trains, compound gear trains, reverted gear trains and planetary gear trains. Each type has its own design and application.

Simple gear trains are a series of gears that transmit motion from one to another.

Compound gear trains have multiple gears on the same shaft, allows for more speed and torque variation.

Reverted gear trains has the input and output gears on the same axis for compactness.

And planetary gear trains has a central gear (the sun) surrounded by gears (the planets) that orbit around it, good for complex systems that requires high torque and speed reduction.

What is an example of a gear train?

A good example of a gear train is in an automatic transmission system in vehicles.

Here gear trains are used to adjust the speed and torque between the engine and the wheels. The transmission has a series of gears and clutches to change the output shafts speed smoothly, so the vehicle can accelerate and decelerate efficiently.

By engaging different combination of gears the transmission can provide the right power and speed for different driving conditions without human intervention.

Can a gear train change speed?

Yes a gear train can change speed.

By using gears of different sizes a gear train can increase or decrease the rotational speed between the input and output. If the output gear is smaller than the input it will rotate faster; if it’s larger it will rotate slower.

This is important for adjusting the performance of mechanical systems. But if you want the same speed and same direction of rotation both the input and output gears must be the same size.

For a higher gear to reduce speed it must mesh with a smaller gear. This flexibility makes gear trains useful for many engineering applications.