Dont know where to start with your new mechanical design porject? Ive been there too.

I will guide you through this process like Yoda guiding Luke in the ways of the force. Whether you’re a seasoned mechanical engineer looking to brush up on your skills or a newcomer eager to learn the ways of the mechanical designer, these 9 steps will put you on the right path for any project.

Btw., I have some great engineering project ideas if you are looking for some inspiration.

By understanding the steps in the design process, you can be able to define the problem in a simple way so that you can take immediate action.

So, lets start then, shall we?

TLDR

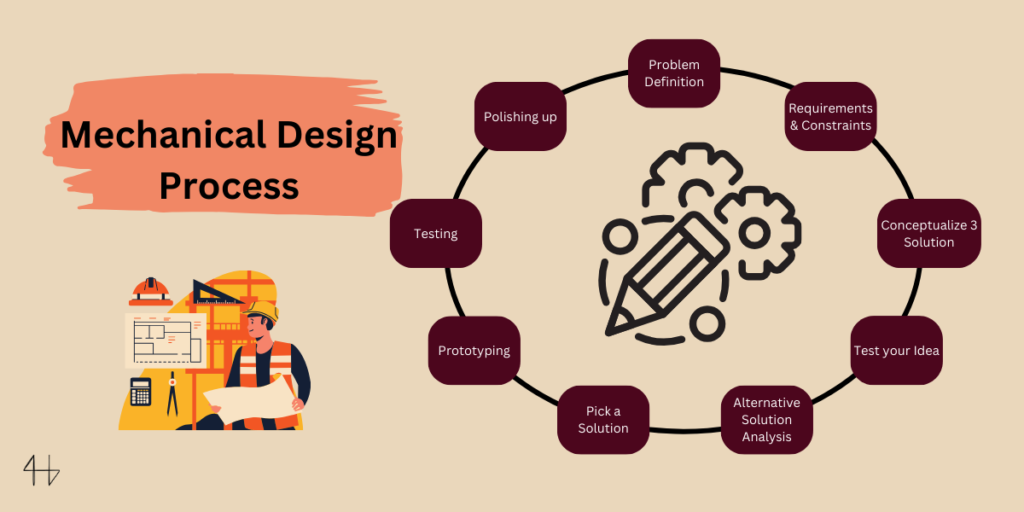

This guide dives into the 9 steps of mechanical design:

- Problem definition

- Requirements and Constraints

- Conceptualize 3 Possible Solutions

- Idea testing

- Alternative Solution Analysis

- Decide on a Solution

- Prototyping

- Testing

- Polish up the Final Solution

What is Mechanical design?

Mechanical design is the development of structures and models that facilitate the creation of mechanical based systems and components.

Basically put, Mechanical design is setting up all of the parts to make building to project effortless and easy.

It encompasses the process of conceptualizing, designing, and refining various elements to ensure functionality, efficiency, and reliability in a wide range of products and applications.

9 Step Mechanical Design Process

When it comes to creating efficient and functional mechanical systems, a well-structured design process is essential. Whether you’re working on intricate mechanical components or tackling large-scale product design projects, following a systematic approach can streamline your workflow and ensure optimal results.

I broke down the nine key steps of the mechanical design process into a simple explainaination – I find that engineering definitions can get confusion like they werent written out by humans.

This should set you on track to designing your own mechanical projects and components.

Step 1: Define the Problem

First things first – define the problem. A problem well defined is already half solved.

In this stage of the mechanical design process you write down clear objectives and understanding the requirements of the project. By having a good understanding of the problem, the mechanical designer can lay a solid foundation for the next steps in the mechanical design process.

You need to answer the questions who, what, and why.

Example: “South Africans need a low cost solution to power generation because the majority of south africans live in poverty and the government is not managing electricity well as a resource.”

This example is an example of a problem statement for low cost commercial windturbine that one might want to build.

Step 2: Requirements and Constraints

In mechanical design, understanding requirements and constraints is key.

Engineers must focus on creating cost-effective solutions while making sure that the project does what it should – meets the requirements.

Balancing these factors (cost, functionality) ensures the final product meets specifications without exceeding budgetary or logistical limitations.

Step 3: Conceptualize 3 Possible Solutions

When tasked with a mechanical design project, the first step is to conceptualize three possible solutions. This stage involves brainstorming ideas and exploring different approaches to address the project requirements.

Utilizing CAD (Computer Aided Design) software helps a lot with visulaising the solid object and how it acts through simulations of finite element analysis.

Additionally, mechanical engineers use the solid models and explore complex geometries to visualize and refine potential design solutions.

Step 4: Idea testing

When starting an engineering design project, explore lots of ideas and choose the one that fits best.

Take these into account when testing your ideas:

- Materials

- Tools

- Math concepts

- Manufacturing

These are other things to consider to make your life easier later on.

Step 5: Alternative Solution Analysis

When faced with a design challenge, explore alternative solutions beyond your initial concept.

Look at competitors.

Look at how the problem you have are solving is already being tackled – it may have nothing to do with what you want to do, but it can give you inspiration.

Consider different devices, components, and assembly methods to address the problem from various angles. By exploring alternatives, you can uncover innovative approaches that may offer superior performance, efficiency, or cost-effectiveness for your project.

Step 6: Decide on a Solution

After exploring various options, it’s time to decide on a solution for your mechanical design project.

Consider these factors to make sure that your solution can be built, does what it shoud, and doesnt break after one use.

- Mechanics

- Maintenance requirements

- Stress analysis

- Manufacturing

Making an informed decision at this stage is crucial for the success of your project.

Step 7: Prototyping

Prototyping is a critical phase in the mechanical design process. It shows if your idea is producable.

You need to select the appropriate manufacturing process to create prototypes of components and assemblies. Through prototyping, mechanical engineers can test and refine designs, ensuring they meet specifications before completing the final product.

Step 8: Testing

Testing is where most of the project spends its time. It is a never ending process.

Test and improve. The higher your standards, the more time you’ll spend testing your solutions.

Utilizing tools like finite element analysis, engineers scrutinize designs for potential weaknesses and optimizations. This phase also involves assessing manufacturability and ensuring the device meets specifications before moving forward in the production process.

Testing takes up half of the v-model design process – the validation half.

Step 9: Polish up the Final Solution

Utilize your skills to refine the design, considering factors like cost-effectiveness and optimal materials. This stage ensures that your solution is not only functional but also meets budgetary constraints and quality standards.

Once your product works smoothly, it is time to you let your artistic brain take control.

Cover the cables, polish it up, paint it, make it pretty.

You want people to look at it and go “Ooooo!”

Why is the Design Process Important?

Mechanical design is crucial for ensuring products function efficiently and reliably.

By carefully engineering the layout and components, designers optimize performance while minimizing costs. This process involves considering factors like material selection, stress analysis, and manufacturing feasibility.

Ultimately, meticulous mechanical design lays the foundation for successful product development and customer satisfaction.

FAQs

What is an example of mechanical design?

An example of mechanical design is the creation of a robotic arm assembly used in manufacturing processes.

What are the basics of mechanical design?

The basics of mechanical design encompass fundamental principles and concepts essential for understanding the discipline. From statics and dynamics to material properties and manufacturing processes, grasping these foundational elements lays the groundwork for mastering the intricacies of mechanical design.

What are the three types of mechanical design?

Mechanical design encompasses three main types: machine design, product design, and system design. Each involves specialized knowledge and considerations, contributing to the architecture of mechanical based systems and components.

What is CAD mechanical design?

CAD (Computer-Aided Design) mechanical design involves utilizing software to create precise digital models of mechanical components and systems. It requires knowledge of engineering principles and the intricacies of CAD software architecture to accurately represent and simulate mechanical designs in a virtual environment.

What is a mechanical designer?

A mechanical designer is a professional with extensive knowledge in the field of engineering, intricately involved in creating and optimizing mechanical based systems and components. They play a crucial role in various industries, from automotive to architecture, contributing their expertise to innovative design solutions.

What does a mechanical design technician do?

A mechanical design technician ensures safety by integrating mechanical systems into structures effectively.

What do mechanical engineers do?

Mechanical engineers ensure safety by designing integrated structures that function efficiently and reliably.

What degrees do I need for mechanical design?

Applied science degree, bachelor’s degree in mechanical engineersing, associate degree.

What is the design process in mechanical engineering

The design process in mechanical engineering is an integrated approach to creating safe and efficient structures and systems. It involves meticulous planning, analysis, and implementation to ensure that the final product meets stringent safety standards while delivering optimal performance.

What is the difference between Mechanical Designers & Mechanical Engineers

Mechanical Engineers generally focus more on onceptualising and designing. Whereas Mechanical designers focus more on detailed technical plans and digital models using CAD and FEA software.

Monarch-Innovation have a really detailed explainaition. Check it out if you want a more in depth answer.