Confused about bevel gears? Don’t be. Problem solved!

If that didn’t help I put everything you need to know about bevel gears in this article.

How do the gear teeth work together in a bevel gear pair, how are they manufactured, what are their standard sizes, and more?

Without a clear understanding, you can end up with a design that doesn’t work or worse, a system that doesn’t work at all. But here’s the good news: by understanding the basics like pitch angle and gear teeth interaction you can solve this puzzle.

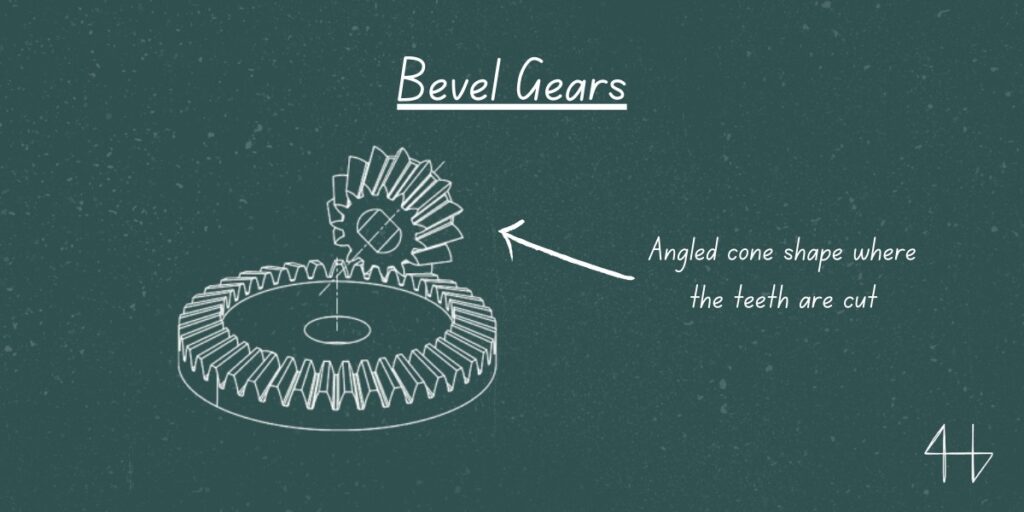

What is a bevel gear?

Bevel gears are a special type of gear used in applications where the shafts intersect, usually at 90 degrees.

Unlike regular gears, bevel gearing is conical in shape and has angled teeth. This allows them to transmit power between the shaft axes and change the direction of rotation.

The interaction is on a conical pitch surface which is critical for speed and torque adjustment in mechanical systems.

The working principle of bevel gears

Simply put, bevel gears change the direction of force between two shafts.

Less simply put, bevel gears work by meshing a bevel pinion with a larger bevel gear.

As the pinion rotates the tooth line of the pinion engages with the corresponding teeth on the bevel gear. This transfers torque and changes the direction of rotation.

The pitch angles of both gears must be matched exactly for smooth operation.

The mounting distance between the gears is also critical for alignment which is essential for optimal performance and to get the mechanical advantage you want. Kinda pointless if the distance between two gears is so large they don’t touch, so be careful.

How to recognize bevel gears?

Bevel gears are just angled gears. They are shaped like shallow cones with teeth. This is to accommodate intersecting shafts.

The teeth can be straight, spiral, or zero, each type affects how the gear meshes and operates.

5 types of bevel gears

Bevel gears come in various types, each for different applications depending on the tooth shape and performance:

- Straight Bevel Gears: These have a simple design with straight teeth, like spur gear, and are used in low-speed applications where simplicity and ease of manufacturing are key.

- Spiral Bevel Gears: With curved teeth, these gears have smoother engagement and quieter operation than the straight tooth ones, so they are used in high-speed applications. Kinda like a bevel helical gear

- Hypoid Bevel Gears: These are like spiral gears but with the axes offset. This design allows for even smoother operation and higher load capacity, used in automotive applications.

- Miter Gears: A special type of bevel gear, miter gears have an equal number of teeth and are used for a 1:1 speed ratio at 90 degrees, so they are perfect for applications where input and output speeds are equal.

- Zerol Bevel Gears: A hybrid design that combines features of both straight and spiral bevel gears. They have the advantages of both, smoother engagement like spiral gears, and the simplicity of straight teeth.

Miter gears vs bevel gears

Miter gears are a special type of bevel gear, with an equal number of teeth on both gears, so a 1:1 gear ratio.

This means they are good at changing the direction of rotation between intersecting shafts without affecting speed or torque. Standard bevel gears can have different tooth counts so they can adjust speed and torque, more flexibility in mechanical design.

Miter gears are good for applications where only direction change is needed, other bevel gears are better when variations in mechanical output are required.

When to use bevel gear

Bevel gears are the way to go when you need to change the direction of rotation between shafts at an angle, often 90 degrees.

They are good when speed and torque adjustment is a priority because they are more flexible than other gears like helical gears.

Bevel gears are best when accuracy is required in power transmission.

Systems like the Gleason system can further improve their performance, for precise engagement and optimal efficiency.

Manufacturing process of bevel gears

Bevel gear manufacturing involves several methods, each for different needs.

Cutting is the most common, where specialized machines shape the teeth with high precision, so good for gears that require accurate and reliable performance.

Casting is another method, used for larger gears. Casting is good for making big components but not good for precision applications since there can be variations in the final product.

Forming is used when a specific shape and profile is needed, so more complex and customized gear design. Each method has its place depending on the size, precision, and specific requirements of the bevel gear being produced.

Applications of bevel gear

Bevel gears are versatility and efficiency which makes them suitable for many applications, from everyday machinery to complex mechanical systems.

Here are some of the key applications where bevel gears are required:

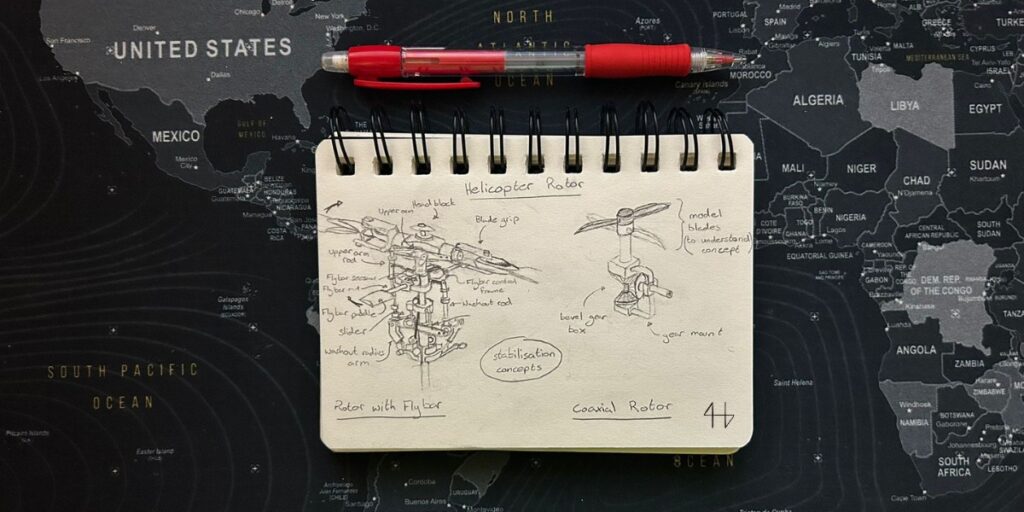

Helicopter Rotor

In helicopter rotors, bevel gears are part of the power transmission system.

They change the direction of the rotational force from the engine to the rotor blades.

This allows the helicopter to achieve the required blade angle and speed for stable flight.

The precision and reliability of bevel gears in this application are critical since they affect the smooth operation and power transmission, directly to the performance and safety of the helicopter.

Steering Systems

In steering systems, bevel gears are the key in transmitting power from the steering wheel to the wheels, for precise directional control.

By converting the rotational motion of the steering wheel into the necessary direction changes for the wheels, bevel gears provide smooth and responsive handling.

Their design allows power transfer at the angle where the steering column meets the steering mechanism, so they are critical in both automotive and machinery steering systems.

Printing Presses

In printing presses, bevel gears are used to control the movement of printing plates with high precision.

They align and synchronize the plates so each print will be accurately transferred to paper. By adjusting the direction and speed of the plate movement, bevel gears maintain the exact positioning required for detailed and consistent print quality.

This is critical in high volume printing where even a slight misalignment can affect the output.

Advantages and disadvantages of bevel gears

Knowing both the advantages and disadvantages will help you decide if it’s the right one for your mechanical system.

Advantages

Disadvantages

Limitations

Bevel gears may be versatile but it has some limitations that may not be suitable for certain applications.

It may struggle in situations where high torque and high speed are required at the same time due to its design limitations.

Bevel gears can also be more complex to manufacture and align, thus more expensive than other gears. These should be considered when deciding if bevel gears are the right for your mechanical needs.

Wrapping things up

Bevel gears are used in mechanical systems that require efficient power transmission and direction change.

Its versatility is seen in the various types and applications, from simple machinery to complex aerospace systems. But to fully utilize its benefits, careful attention to design and installation is required.

Proper selection and alignment will ensure bevel gears will operate well and provide the desired performance and life in your system.

FAQs

Is bevel gear inefficient?

Bevel gear is not inherently inefficient but its performance varies based on design and application.

Properly designed and aligned bevel gear can transmit power efficiently with minimal loss.

However poor alignment or incorrect gear ratio can affect its overall efficiency – even if they are precisely cut.

Are bevel gear expensive?

Bevel gear can be costly depending on the material, precision, and manufacturing method.

Custom or high-precision bevel gear like those used in aerospace applications are more expensive.

But standard bevel gear is generally affordable and good value for many industrial applications.

Does bevel gear have backlash?

Yes, bevel gear can have backlash.

Backlash is the small gap between the gear teeth that causes a delay in movement when direction changes – the play of the gear train.

Are bevel gears noisy?

Bevel gear can be noisy especially if it’s straight bevel gear.

The spiral bevel gear is designed to be quieter due to its smooth tooth engagement.

Proper alignment, high-quality manufacturing, and lubrication can also reduce noise in bevel gear systems.